Products

Our products are known for their outstanding performance and satisfying our clients by providing a sizable increase in productivity.

Products

Our products are known for their outstanding performance and satisfying our clients by providing a sizable increase in productivity.

Taps is one of our primary products that we specialize in. These are the most widely used tools to machine internal threads by cutting or forming method.

Based on Customer’s Application we cater a wide range of options to meet the desired finish, tool life and cost per component.

We deal in all standard, non-standard sizes and customized solutions.

We try to cater complete range of taps in terms of tap material, sizes, design types, coatings, industry standards, thread forms, industry requirements and suitability as per application material

Inquiries for Special Tolerance, Dimension Lengths, Through Coolant and High-Performance Coatings are also catered on request.

Thread Mill is a trending alternative with a versatile approach to machining of Internal & External Threads. These are ideal for complicated thread profiles, low clearance and high-speed machining applications.

We are happy to offer a wide range of Threading Tool options in various sizes, thread forms and geometries to machine a wide range of application materials.

Non-standard tools are also available on request.

Thread Cutting Dies are widely used for External Threading Applications. We cater a wide range of precisely ground dies with excellent surface finish of thread flanks and cutting edges.

We are glad to offer a broad range in various sizes, thread forms and tool material.

Solid Carbide and Carbide Brazed Thread Dies are also available on request.

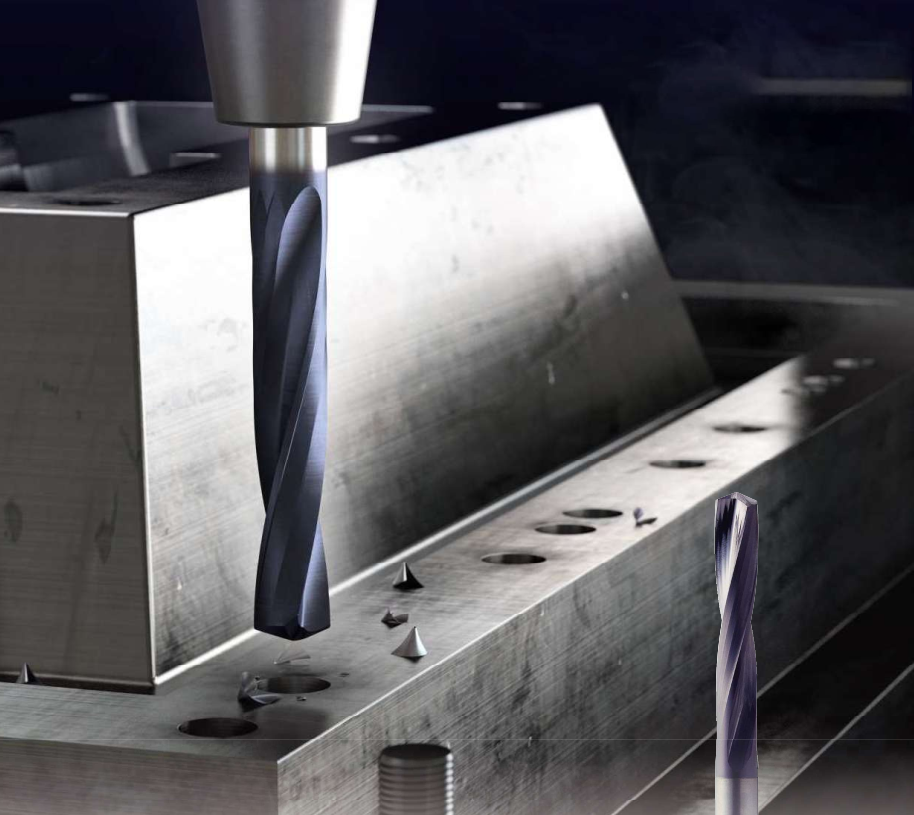

Hole Making is a crucial and intensive part of machining process. We cater a wide range of options in this segment with advanced design geometries that bring out extraordinary performance and cover multiple applications.

Our range encapsulates Drills, Reamers, Boring Bars and Other Cutting Tools on offer in HSS, HSS-E, HSS-PM Grades, Solid Carbide, Indexable and Carbide Brazed form.

We have tried and tested solutions to provide long tool life, high wear resistance at competitive pricing to improve CPC with minimised tool breakage.

We also specialize in making customized Round Tools such as Drills, Step-Drills, Reamers, Hole-Mills and Other Special Tools in High Grade HSS-Co and PM Material. With carefully designed geometries and manufactured on state of the art 5-Aixs CNC Grinders, we have proven excellent results in SPM and CNC machine production applications. Our product range offers Tool Life much higher than HSS and cost-effectiveness better than solid carbide.

Suitable High Performance Coatings and Through Coolant features are also available on request.

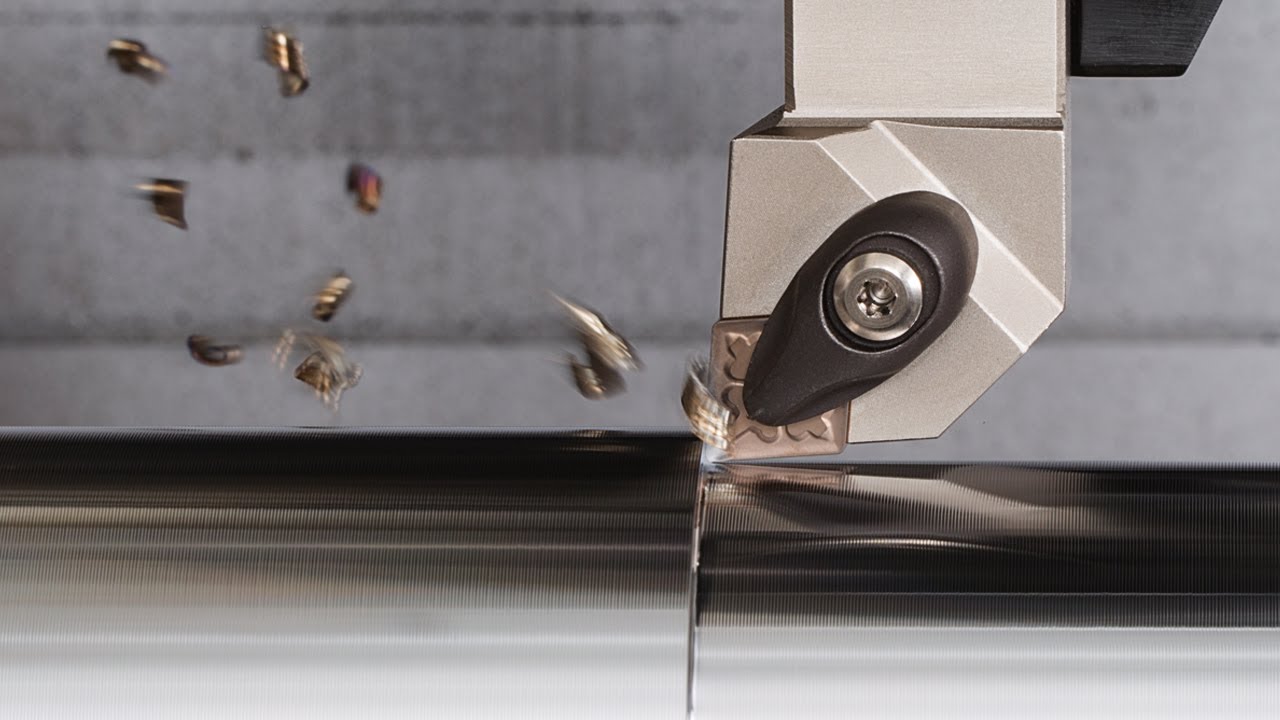

We cater a wide range of Inserts for Turning, Facing, Parting and Grooving Operations. Our products are capable of high cutting performance for general applications as well as harsh & challenging conditions.

Variety of Geometries are available in multiple carbide grades. Special chip-breaking designs have been carefully designed to combat with tough materials and heavy interruption applications.

High quality inserts in PVD and CVD coating options are available, that offer high tool life and increased productivity at competitive prices!

We have an extensive range of Milling Tools that are cost efficient, run on high parameters and bear excellent machining ability.

The product range is categorised to cover various work materials and applications in standard and customised sizes.

Our milling range covers both cost-effective solutions focussed on roughing & high material removal requirements And advanced range to machine challenging materials with high performance, maintaining close tolerance and generate excellent surface finish.

Customised tool geometries & grades are available, specific to the customer’s requirement, be it heavy cutting, high speed machining, hard materials, soft & sticky materials, dry cutting, roughing/finishing etc.

All kinds of high performance HSS, HSS-E, HSS-PM and Solid Carbide Round tools as well as Indexable Milling options are available.

Tool Holding System is one of the most important factor for tool life. We have an extensive range of Holding systems with excellent clamping, accuracy and repeatability for CNC Machines for all kinds of machining applications. All products are precisely balanced and ruggedly designed. We deal in both standard and special holding system requirements. Precision Collets and accessories are also available.

We also bear expertise in wide range of Tapping Holders for Conventional Machines. These are specially designed to compensate the lack of accuracy and feed control of such machines. Our range is a proven solution to simplify tool holding arrangement, minimise tap breakage and extend longevity of not only the tools but machine spindles as well. Quick Change Holders and Adaptors in Standard and Customized options are also available.

We also deal in Reversible and Non-Reversible Tapping Attachments for conventional machines with a combination of features like Rigid type, Radial Floating and Axial Length Compensation.

Screw thread inserts are a convenient method to repair damaged thread or create stronger original threads in a component. In addition to offering tools & gauges for machining of STI / Helicoil Hole and Threads applications, we also deal in supplying good quality thread inserts as per customer’s requirements.

These are available in all popular thread forms, durable material and consistent quality for applications in Aerospace, Automotive and Other Industries.

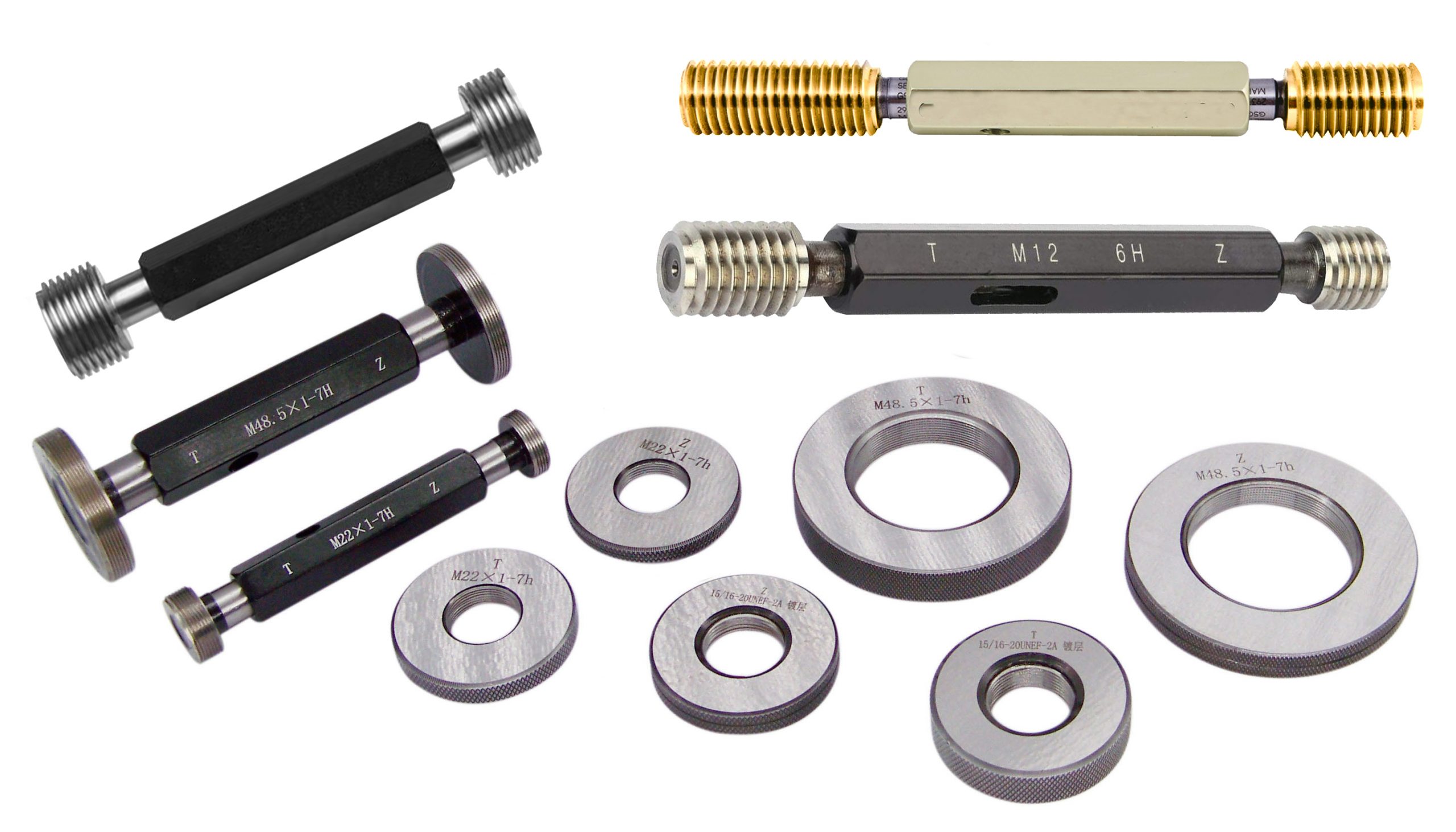

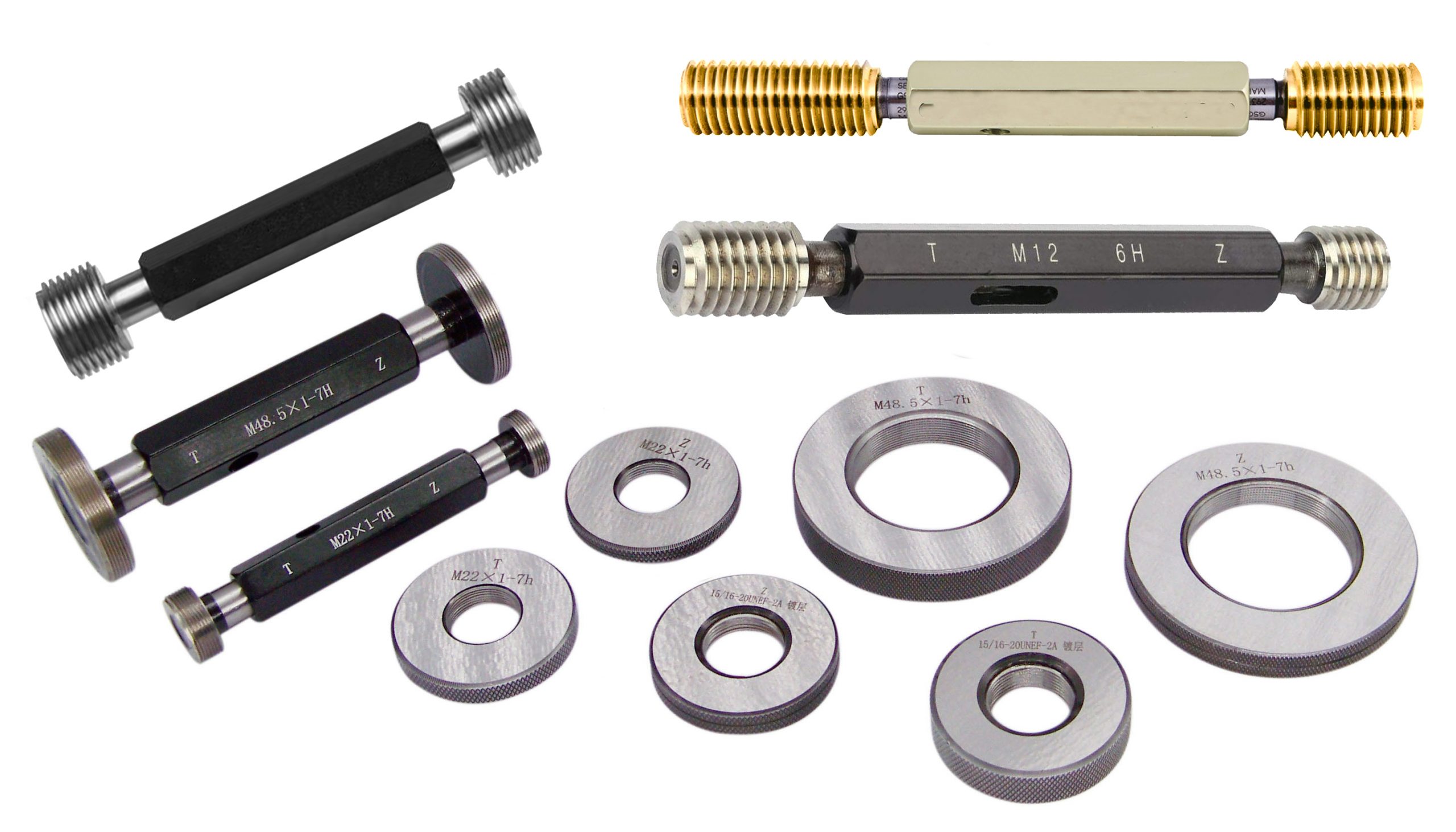

The mark of consistency in quality is inevitable without reliable and regular gauging during production. We deal in High Quality Thread Plug Gauges and Ring Gauges in all Major Thread Forms such as Metric, British Standard, UN, Taper Threads etc. Special Gauges in High Grade Steel and Solid Carbide material, miniature gauges, customised / non-standard gauges and high-performance Coatings on gauges are also available on request.

One of the most vital factor for optimum tool performance is Cutting Oil. The recipes of products we have to offer are carefully designed with high quality additives and thoroughly tested after lot of R&D and hands-on trial experience. The resultant oils offer excellent lubrication, high load bearing capacity, cooling properties and easy chip evacuation.

Our products help in preventing material welding, tool/component burning and provide superb finish. Special Pneumatic Spray Units for fast production applications and minimum oil wastage are also available.

Taps is one of our primary products that we specialize in. These are the most widely used tools to machine internal threads by cutting or forming method.

Based on Customer’s Application we cater a wide range of options to meet the desired finish, tool life and cost per component. We deal in all standard, non-standard sizes and customized solutions.

We try to cater complete range of taps in terms of tap material, sizes, design types, coatings, industry standards, thread forms, industry requirements and suitability as per application material

Inquiries for Special Tolerance, Dimension Lengths, Through Coolant and High-Performance Coatings are also catered on request.

Thread Mill is a trending alternative with a versatile approach to machining of Internal & External Threads. These are ideal for complicated thread profiles, low clearance and high-speed machining applications.

We are happy to offer a wide range of Threading Tool options in various sizes, thread forms and geometries to machine a wide range of application materials.

Non-standard tools are also available on request.

Thread Cutting Dies are widely used for External Threading Applications. We cater a wide range of precisely ground dies with excellent surface finish of thread flanks and cutting edges.

We are glad to offer a broad range in various sizes, thread forms and tool material.

Solid Carbide and Carbide Brazed Thread Dies are also available on request.

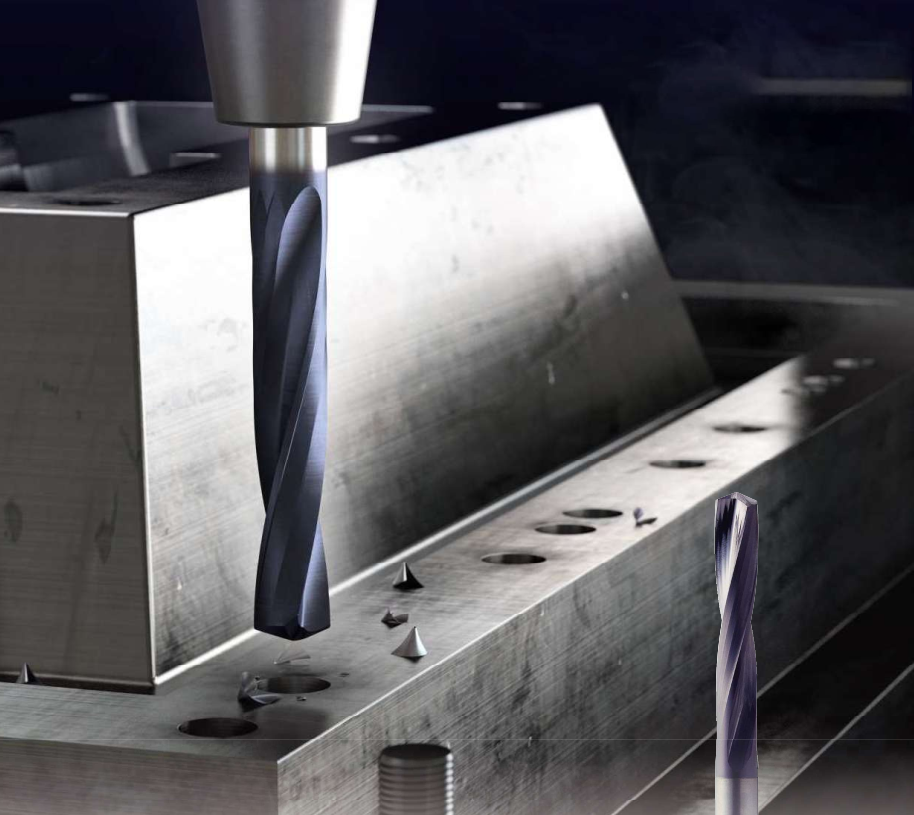

Hole Making is a crucial and intensive part of machining process. We cater a wide range of options in this segment with advanced design geometries that bring out extraordinary performance and cover multiple applications.

Our range encapsulates Drills, Reamers, Boring Bars and Other Cutting Tools on offer in HSS, HSS-E, HSS-PM Grades, Solid Carbide, Indexable and Carbide Brazed form.

We have tried and tested solutions to provide long tool life, high wear resistance at competitive pricing to improve CPC with minimised tool breakage.

We also specialize in making customized Round Tools such as Drills, Step-Drills, Reamers, Hole-Mills and Other Special Tools in High Grade HSS-Co and PM Material. With carefully designed geometries and manufactured on state of the art 5-Aixs CNC Grinders, we have proven excellent results in SPM and CNC machine production applications. Our product range offers Tool Life much higher than HSS and cost-effectiveness better than solid carbide.

Suitable High Performance Coatings and Through Coolant features are also available on request.

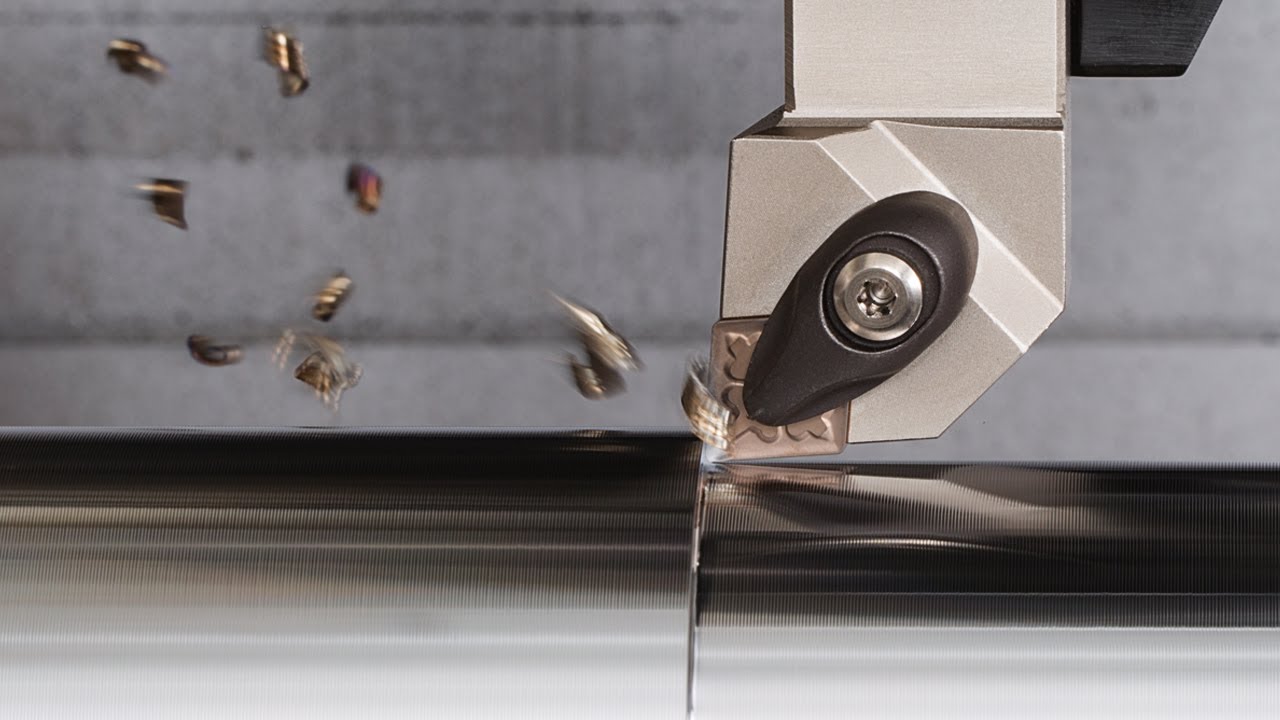

We cater a wide range of Inserts for Turning, Facing, Parting and Grooving Operations. Our products are capable of high cutting performance for general applications as well as harsh & challenging conditions.

Variety of Geometries are available in multiple carbide grades. Special chip-breaking designs have been carefully designed to combat with tough materials and heavy interruption applications.

High quality inserts in PVD and CVD coating options are available, that offer high tool life and increased productivity at competitive prices!

We have an extensive range of Milling Tools that are cost efficient, run on high parameters and bear excellent machining ability.

The product range is categorised to cover various work materials and applications in standard and customised sizes.

Our milling range covers both cost-effective solutions focussed on roughing & high material removal requirements And advanced range to machine challenging materials with high performance, maintaining close tolerance and generate excellent surface finish.

Customised tool geometries & grades are available, specific to the customer’s requirement, be it heavy cutting, high speed machining, hard materials, soft & sticky materials, dry cutting, roughing/finishing etc.

All kinds of high performance HSS, HSS-E, HSS-PM and Solid Carbide Round tools as well as Indexable Milling options are available.

Tool Holding System is one of the most important factor for tool life. We have an extensive range of Holding systems with excellent clamping, accuracy and repeatability for CNC Machines for all kinds of machining applications. All products are precisely balanced and ruggedly designed. We deal in both standard and special holding system requirements. Precision Collets and accessories are also available.

We also bear expertise in wide range of Tapping Holders for Conventional Machines. These are specially designed to compensate the lack of accuracy and feed control of such machines. Our range is a proven solution to simplify tool holding arrangement, minimise tap breakage and extend longevity of not only the tools but machine spindles as well. Quick Change Holders and Adaptors in Standard and Customized options are also available.

We also deal in Reversible and Non-Reversible Tapping Attachments for conventional machines with a combination of features like Rigid type, Radial Floating and Axial Length Compensation.

Screw thread inserts are a convenient method to repair damaged thread or create stronger original threads in a component. In addition to offering tools & gauges for machining of STI / Helicoil Hole and Threads applications, we also deal in supplying good quality thread inserts as per customer’s requirements.

These are available in all popular thread forms, durable material and consistent quality for applications in Aerospace, Automotive and Other Industries.

The mark of consistency in quality is inevitable without reliable and regular gauging during production. We deal in High Quality Thread Plug Gauges and Ring Gauges in all Major Thread Forms such as Metric, British Standard, UN, Taper Threads etc. Special Gauges in High Grade Steel and Solid Carbide material, miniature gauges, customised / non-standard gauges and high-performance Coatings on gauges are also available on request.

One of the most vital factor for optimum tool performance is Cutting Oil. The recipes of products we have to offer are carefully designed with high quality additives and thoroughly tested after lot of R&D and hands-on trial experience. The resultant oils offer excellent lubrication, high load bearing capacity, cooling properties and easy chip evacuation.

Our products help in preventing material welding, tool/component burning and provide superb finish. Special Pneumatic Spray Units for fast production applications and minimum oil wastage are also available.